BF-762

Fall 2019

Toggle locks are cool, belt-feeds are cool.

I wanted to build a higher-powered rifle with a locked breech for a while, and why not make a belt-fed rifle too? Since a belt-fed rifle will obviously go through a lot of ammunition so this limited me to cheap cartridges for economic reasons. That meant I had to go with, basically, .22lr, 9mm, 5.56mm, or 7.62x39mm. The first two are a little too light for what I wanted. From the last two, 7.62x39 is more powerful while having lower pressures and more case taper, which makes it easier to work with.

The design uses a toggle-locked system, similar to the Luger pistol. When the gun is in battery, the toggle is slightly over-center, preventing the bolt from opening. However, unlike the Luger, which unlocks the toggle via recoil operation, the BF762 is gas-operated. A gas piston is pushed forward by the high-pressure gas from a port under the barrel, pulling on a linkage that forces the toggle open. By designing the gas piston to be pulled forward instead of pushed backwards, the piston rod is kept under tension, so that it can be made smaller without buckling. The bolt features vertical grooves that engage with a round from the belt and pull it backwards out of the belt. A flat spring forces the cartridge to slide down the grooves, displacing the previous case and aligning the new cartridge with the chamber. When the bolt closes again, the top of the grooves spring over the next round in the belt. Feeding the belt forward is done via a set of pawls on the left side of the gun, which push the next round into position as the bolt is moving forward, due to the action of a cam on the bottom of the piston rod.

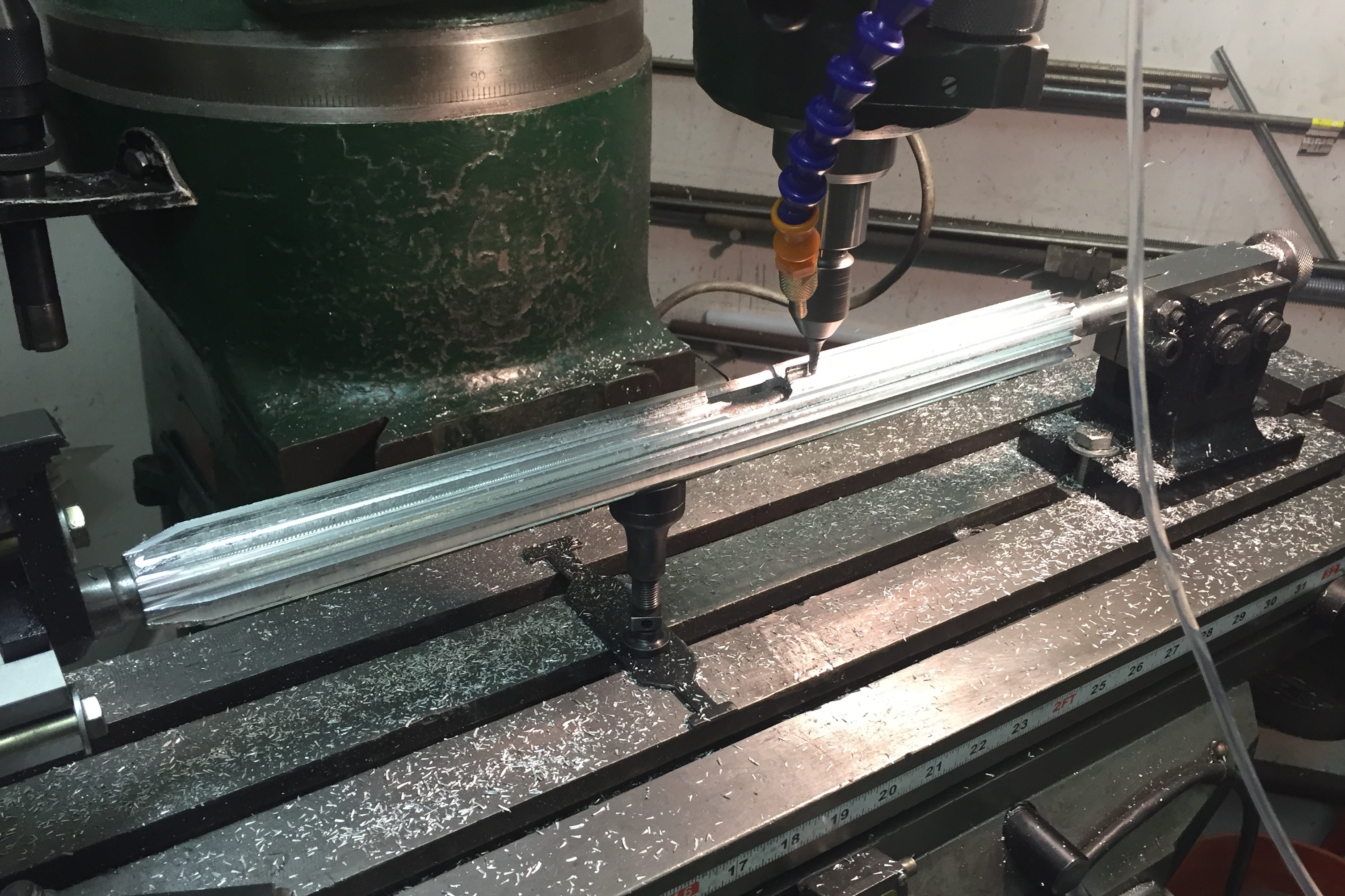

The gun is also air-cooled, featuring a large aluminum finned jacket around the barrel. The fit between the jacket and the barrel is not nearly as good as I'd like, but the first 6 inches of the barrel, which usually would get the hottest, have a bronze bushing made that allowed me to get a very close fit with the jacket to maximize heat tranfer. I'm not sure if I'm actually helping anything or not, so I'll have to do some testing to see if the jacket is actually increasing heat dissipation.

The cooling jacket being machined.

While I had initially thought I might try using electro-chemical machining to make the barrel, I ultimately decided I was too busy to experiment with that, so I'm just using a slightly modified M70 barrel.

I've had many major problems with this gun so far. One was that the relatively small size of the fire control group did not allow a strong enough hammer spring to trigger the notoriously hard primers of cheap surplus Russian 7.62x39 ammunition. This is not an uncommon problem, and there are many popular professionally manufactured rifles (like the mini-14) that can't fire that hard-primed ammo, so I'm not terribly upset aside from now needing to pay a lot more for the ammunition to get American ammunition that has much softer primers. That became a big problem when Coronavirus hit, and ammunition became unobtainable. The second problem was that it was difficult to get enough impulse from the gas piston to fully cycle the action. This was entirely my fault, as I had a misconception that the gas-operation was a source of nearly unlimited energy, and I was very concerned about overgassing the system. So ultimately the gas port was placed too far forward on the barrel, and the duration of the piston impulse was too low. I reduced the hammer-spring force, reduced the strength of the recoil springs, increased the diameter of the gas piston, and lapped a few sealing surfaces that were just a bit too tight. That was enough to get the rifle to fully cycle so long as the belt feeding mechanism was disconnected.

So then I had to deal with feeding the belt a different way. Ultimately though, I wasn't able to get anything to work reliably, and because of coronavirus panic, I only had 10 rounds to test with. Literally just 10. Thousands of rounds of wolf ammo with primers too hard to use, but only 10 rounds of soft-primed ammo. Because of this, I decided to pivot to magazine-feeding, and made an adapter to let the rifle feed from modified single-stack AK magazines, because that's all I had on-hand that I thought I could make work. That still failed though, my guess is that the modified feed spring combined with increased force to pull the round back meant the round kept slipping off the feed claw, and so I was never able to get the gun to cycle, and I finally ran out of ammunition to test with. So now this project is on hold until I get my hands on more soft-primed ammo.